|

|

OLYMPUS iPLEX NX Industrial Videoscope

The IPLEX NX brings you the most advanced technologies in IPLEX series. It provides a bright, high-resolution image even in large spaces through a high-quality image sensor, bright laser diode light source, high-level image processing technology, and Olympus's optical lens technology.

- High-Quality Images

- Expanded Measurement Capabilities

- Improved Inspection Efficiency

High-Quality Images for Clear Visualization

The IPLEX NX is engineered to deliver high-resolution images. Its reliable image quality enables users to clearly identify trouble spots and defective areas, so inspectors can make correct judgments about crucial systems and technologies.

Exceptional Brightness and Impressive Images

View target areas clearer than ever before with IPLEX NX. A trio of enhancements - improved high-resolution CCD technology, intensely-bright laser diode illumination, and the innovative PulsarPic processor - achieve unprecedented image quality that is four times brighter than a conventional videoscope. Inspection targets are brightly illuminated even in large, wide spaces.

Noise Reduction (NR) Algorithm Control

Image noise, such as false color, often occurs on glossy surfaces, and random noise in low luminance images can be an obstacle for strict inspections. The new PulsarPic system carries our latest Noise Reduction (NR) algorithm fine-tuned for the IPLEX NX to generate images with less noise for easier decision-making.

Please click on the image to get the larger view.

Large Touch-Screen Monitor

A vivid 8.4-inch touch-screen monitor delivers clear, bright images that are readable in any light.

Featuring an 8.4-inch screen, the largest in the IPLEX series, the IPLEX NX displays images that are 1.7 times larger than that of a conventional 6.5-inch monitor.

Comparison of Image Sizes

Excellent Image

Scrutinize the subtlest defects in the darkest or most reflective places and over wide areas with clear, bright images. The IPLEX NX videoscope’s sophisticated technology means you get the highest quality images possible for fast and precise inspections.

IPLEX NX | Conventional model (IPLEX FX) | ||

Exceptional Resolution | Melted Material |

|

|

Outstanding Brightness | Turbine |

|

|

Realistic Color Reproduction | Welding |

|

|

Advanced Noise Reduction | Combustion Chamber |

|

|

Expanded Measurement Capabilities

The IPLEX NX is designed to make precise 3D measurements. Put Olympus’ advanced videoscope technology to work to get inspections that are precise and efficient.

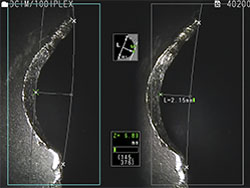

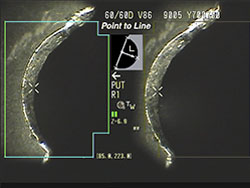

Super Wide Field Stereo Measurement

Stereo Measurement measures the size or depth of defects such as cracks found during inspection. The redesigned optical system and enhanced technology achieve a dramatic expansion in the inspection area. Users can now identify and measure flaws from 2X further away in an inspection area 4X larger than conventional videoscopes. Stereo Measurement supplies 3D space information for specific points in an image through precise triangulation, providing accurate length, depth, and shape measurements. The IPLEX NX is designed, manufactured, and fine-tuned to deliver superior accuracy and image quality so inspectors can detect small cracks or defects that were previously measurable only at very close range.

* When contrasted with conventional φ6.0 mm scope model with a direct-viewing stereo optical adaptor.

IPLEX NX extended measurement area (left) can measure previously non-measurable types of defects (right)

Larger inspection area makes it easier to observe larger defects.

* Even if the measurement is performed from the twice apart distance, IPLEX NX is as precise as a conventional model.

** In case of using φ6.0mm scope with direct-viewing stereo optical adapter, the diagonal length of the inspection area of IPLEX NX is almost 4 times of the conventional model.

Note: Actual viewing angle is wider than shown in this illustration.

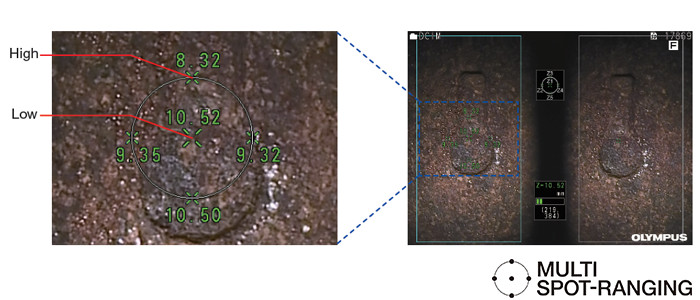

Multi Spot-Ranging

The IPLEX NX features a unique multi Spot-Ranging function, enabling real-time measurement of the distance from the scope tip to multiple points on the inspection surface. This provides real-time surface shape information with no pause or break in the inspection.

Improved Inspection Efficiency

The IPLEX NX is simple to operate and user friendly. Even during long inspections, the NX delivers user comfort and excellent maneuverability, thanks to interchangeable scope units and TrueFeel scope tip articulation.

Multi-Position Design

The IPLEX NX can be configured six different ways to maximize user comfort. The touch-screen monitor can be positioned to maintain comfort when using the IPLEX NX in different environments. The monitor can even be detached from the main unit for added flexibility and convenience. Use the optional handheld remote controller for the utmost light and tactile control.

1.Bar top Style, 2.Up right Style, 3.Compact Style, 4.Flat Style, 5.Separate Style, 6.Case top Style

Interchangeable Scope Units

Pick the right one to fit the job. A single NX videoscope can be configured for varied inspections, with 6.0 mm scopes ranging in length from 3.5 m to 7.5 m and 4.0 mm scopes with lengths of 3.5 m and 5 m.

TrueFeel

A newly employed electric motor further enhances TrueFeel operation, achieving rapid and responsive movement. Inspectors can easily control the scope through lightweight, comfortable operation that lessens user fatigue.

![]()

The Durable Tapered Flex Insertion Tube

Tapered Flex insertion tube combines superb maneuverability with optimized rigidity and flexibility for smooth scope insertion, enabling you to reach target areas quickly and easily. Insertion tubes feature four layer construction with a tungsten outer braid for durability and resilience.

![]()

The Ghost Image Function

Ghost Image enables inspectors to compare live images with images stored on the videoscope to contrast past and present conditions. This function makes it easier to monitor changes in components over time.

InHelp Inspection Assist Software

InHelp inspection assist software simplifies data input and management, improving efficiency, simplifying inspections, and organizing stored images. Optional data sets provide a structure to manage your images.

InHelp inspection assist software (for reporting) makes your routine work simple and easy. With optional report templates matched to data sets, you can generate detailed reports with a few clicks.

Image sharing (optional)

Wireless-LAN connectivity enable multiple experts to monitor remote procedures at the same time by using an SD card equipped with commercially available wireless LAN, enhancing analysis speed and inspection accuracy.

*Confirmed with Toshiba FlashAirWireless LAN SD card(operability confirmed)

| SCOPE UNIT | ||||||

| Model No | IV9435N | IV9450N | IV9635N | IV9650N | IV9675N | |

| Insertion tube | Scope diameter | φ4.0 mm | φ4.0 mm | φ6.0 mm | φ6.0 mm | φ6.0 mm |

| Scope length | 3.5 m | 5.0 m | 3.5 m | 5.0 m | 7.5 m | |

| Exterior | High-durability tungsten braid | |||||

| Tube flexibility | Uniform stiffness | Tapered Flex insertion tube with flexibility gradually increasing toward the distal end. | ||||

| Optical system | Field of view | Selectable by optical tip adapter Adapter for Stereo measurement attachable | ||||

| Direction of view | ||||||

| Illumination | High-intensity laser diode | |||||

| Articulation Section | Articulation angle up/down/right/left | 130° | 180° | 150° | ||

| Articulation operation | TrueFeel scope tip articulation with electronic power-assist. | |||||

| BASE UNIT | ||||||

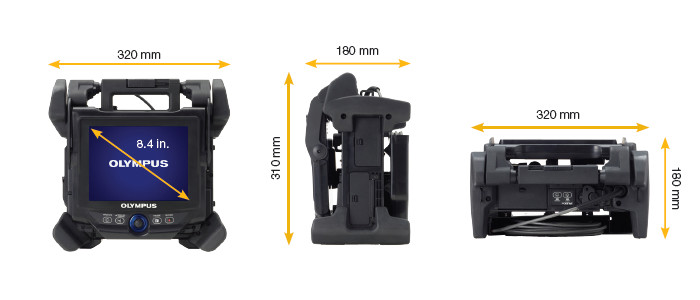

| Dimensions (W xD x H) | 320(W) x 310(H) x 180(D) mm | |||||

| Weight | 3.9 kg | |||||

| Approx. system weight (with battery and SDHC card) | 7.1 kg | 7.2 kg | 7.3 kg | 7.4 kg | 7.6 kg | |

| LCD monitor | 8.4-inch daylight-view touch screen LCD, clear type | |||||

| Input/Output Terminal | Input terminal | S-Video | ||||

| Output terminal | VGA | |||||

| USB connector | Type A connector, Version 2.0 standards | |||||

| Power supply | Battery: 14.8 V nominal, approx. 100-minute operating time. AC power: 100 V to 240 V, 50/60 Hz (with supplied AC adaptor) | |||||

| Recording media | SDHC card and USB flash memory(Still image recording only) | |||||

| Still image recording | Resolution | H768 x V576 (Pixel) | H1024 x V768 (Pixel) | |||

| Recording format | Compressed JPEG format | |||||

| Video recording | Resolution | H768 x V576 (Pixel) | H1024 x V768 (Pixel) | |||

| Recording format | MPEG-4 AVC (H.264) format, Windows Media Player compatible | |||||

| Stereo measurement | Distance | Distance between two points. | ||||

| Point-to-line | Perpendicular distance between a point and a user-defined line. | |||||

| Depth | Orthogonal depth/height distance between a point and a user-defined plane. | |||||

| Area/Lines | Multiple point circumference and area measurement. | |||||

| Optical Adapter Specifications | ||||||

| OPTICAL ADAPTER VARIATION | ||||||

| Optical system | Distal end | |||||

| Field of view | Direction of view | Depth of field*1 | Outer diameter*2 | Distal end*3 | ||

| φ4.0 mm Optical Adapters | AT80D/FF-IV94N | 80° | Forward | 35 to ∞ mm | φ4.0 mm | 20.1 mm |

| AT120D/NF-IV94N | 120° | Forward | 2 to 200 mm | φ4.0 mm | 20.2 mm | |

| AT120D/FF-IV94N | 120° | Forward | 17 to ∞ mm | φ4.0 mm | 20.1 mm | |

| AT100S/NF-IV94N | 100° | Side | 2 to 15 mm | φ4.0 mm | 22.9 mm | |

| AT100S/FF-IV94N | 100° | Side | 8 to ∞ mm | φ4.0 mm | 22.9 mm | |

| AT70D/70D-IV94N | 70°/70° | Forward | 5 to 200 mm | φ4.0 mm | 22.3 mm | |

| AT50S/50S-IV94N | 50°/50° | Side | 3 to 150 mm | φ4.0 mm | 26.7 mm | |

| φ6.0 mm Optical Adapters | AT50D/FF-IV96N | 50° | Forward | 50 to ∞ mm | φ6.0 mm | 21.3 mm |

| AT80D/FF-IV96N | 80° | Forward | 20 to ∞ mm | φ6.0 mm | 21.3 mm | |

| AT120D/NF-IV96N | 120° | Forward | 7 to 300 mm | φ6.0 mm | 21.4 mm | |

| AT120D/FF-IV96N | 120° | Forward | 19 to ∞ mm | φ6.0 mm | 21.4 mm | |

| AT120S/NF-IV96N | 120° | Side | 4 to 150 mm | φ6.0 mm | 26.6 mm | |

| AT120S/FF-IV96N | 120° | Side | 20 to ∞ mm | φ6.0 mm | 26.6 mm | |

| AT90D/90D-IV96N | 90°/90° | Forward | 5 to 250 mm | φ6.0 mm | 25.0 mm | |

| AT70S/70S-IV96N | 70°/70° | Side | 4 to 250 mm | φ6.0 mm | 31.2 mm | |

*1. Indicates the viewing distance with optimal focus.

*2. The adaptor can be inserted into a ø4.0 mm and ø6.0 mm hole when it is mounted on the scope.

*3. Indicates the length of the rigid portion at the scope’s distal end when mounted.

| IPLEX NX OPERATING ENVIRONMENT | ||

| Operating temperature | Insertion tube | In air : -25 to 100 °C |

| Other parts | In air : -21 to 49 °C(with battery) | |

| In air : 0 to 40 ℃ (with AC power adapter) | ||

| Relative humidity | All parts | 15 to 90 % |

| Liquid resistance | All parts | Operable when exposed to machine oil, light oil or 5 % saline solution. |

| Waterproofing | Insertion tube | Operable under water with viewing tip adaptor attached. Not operable underwater with stereo measurement tip adaptors. IV94 series - Up to an equivalent to 5 m (16.4 ft) in depth. IV96 series - Up to an equivalent to 7.5 m (24.6 ft) in depth |

| Other parts | Operable in blowing rain conditions (battery compartment must be closed). Not operable under water. | |

| MIL-STD COMPLIANCE | |

| The operating environment performance is confirmed by the following MIL-STD-810F/G and MIL-STD-461F. No warranty is given as to damage-free under any conditions. Please ask Olympus sales representative for details. | |

| Type | Method |

| Vibration | MIL-STD-810G, Method 514.6, Procedure Ⅰ (General vibration test) |

| Shock | MIL-STD-810G, Method 516.6, Procedure Ⅳ (Transit drop test) |

| Water Resistance | MIL-STD-810G,Method 506.5, Procedure Ⅰ (Rain and Blowing rain test) |

| Humidity | MIL-STD-810G,Method 507.5 |

| Salt Fog | MIL-STD-810G, Method 509.5 |

| Sand and Dust | MIL-STD-810G, Method 510.5, Procedure Ⅰ (Blowing dust test) |

| Icing/Freezing Rain | MIL-STD-810G, Method 521.3 |

| Electromagnetic Interference (EMI) | MIL-STD-461F Above Deck |

| Explosive Atmosphere | MIL-STD-810G, Method 511.5 (Operation in an explosive atmosphere test) |

DIMENSIONS

Remote Control Unit

MAJ-2260

This small handheld remote controller enables users to easily adjust functions such as brightness, zooming, display switching, recording, joystick operation, spot ranging, activating the measurement function, etc.

Long LCD Cable

MAJ-2261

This 2-meter long LCD cable enables inspection while placing the main unit and the monitor up to 2 meters from each other.

Rigid Sleeve Sets

MAJ-1253 (for 6.0 mm insertion tube)

MAJ-1737 (for 4.0 mm insertion tube)

Sets are available for 6.0 mm and 4.0 mm scopes. Each set consists of three rigid sleeves in lengths of 250 mm, 340 mm, and 450 mm.

Lithium-Ion Battery

Lithium-Ion Battery

NP-L7S

Battery Charger

JL-2PLUS/OL-0 (115 V type)

JL-2PLUS/OL-1 (220 V type)

The carrying case is designed to carry one battery charger and two batteries. With a full set of batteries, the IPLEX NX system is ready for inspection anywhere, anytime.

Optical Adapter

The IPLEX NX has a complete and comprehensive range of tip adaptors to meet the optical requirements of any application.

Smart Tip™

*Smart Tip is a function to recognize the optical adapter automatically.

Scope Case

MAJ-2262

Interchangeable scope units can be safely stowed and carried comfortably to inspection venues.

| iPLEX NX Industrial Videoscopes | English - 2.6 MB |

Ελ. Βενιζέλου 7 & Δελφών, 14452 Μεταμόρφωση, Αθήνα, Ελλάδα |