|

|

38DL PLUS

Προηγμένες δυνατότητες, ευκολη χρήση, υψηλή αντοχή, αξιόπιστο

Το 38DL PLUS αποτελεί την ναυαρχίδα της σειράς παχυμέτρων της OLYMPUS και σηματοδοτεί μια νέα εποχή στην παχυμέτρηση με υπερήχους. Είναι ιδανικό σχεδόν για κάθε εφαρμογή, αφού είναι συμβατό με μία πλήρη σειρά μονών και δίδυμων αισθητήρων. Σχεδιασμένο με γνώμονα την ευκολία στην χρήση, με βάρος μόλις 800gr και την αντοχή, κατασκευασμένο βάση προτύπου IP67 και MIL-STD 810.

Διαθέτει έγχρωμη οθόνη VGA, η οποία παραμένει ευδιάκριτη ακόμα και κάτω από το φως του ηλίου. Εργονομικό πληκτρολόγιο που μπορεί να λειτουργεί, είτε με το αριστερό είτε το δεξί χέρι ενώ ενσωματώνει πλήκτρα άμεσης πλοήγησης για εύκολη πρόσβαση σε όλες τις λειτουργίες.

Βασικά Χαρακτηριστικά

• Dual and single element transducer compatibility

• Wide thickness range: 0.08 mm (0.003 in.) to 635 mm (25 in.) depending on material and transducer selection

• Corrosion thickness gaging with dual element transducers

• THRU-COAT® and Echo-to-Echo measurements on painted and coated surfaces

• Internal Oxide/Scale software option

• Standard resolution of 0.01 mm or 0.001 in. for all transducers

• High Resolution software option of 0.001 mm or 0.0001 in. with single element transducers 2.25 MHz to 30 MHz

• Multilayer software option for measurements of up to four layers simultaneously

• High Penetration software option for attenuating materials such as fiberglass, rubber and thick casting

• Thickness, Velocity, and time-of-flight measurements

• Differential mode and Reduction Rate mode

• Time-based B-scan mode; 10,000 reviewable readings per scan

• Olympus High Dynamic Gain technology with digital filters

• V-Path Builder for custom V-path compensation

• Designed for EN15317

Διαθέτει:

- Έγχρωμη οθόνη VGA

- Εσωτερική και Εξωτερική MicroSD

- USB και θύρες επικοινωνίας RS-232

- Έξοδος VGA για σύνδεση με τον υπολογιστή ή οθόνη

Specifications

| Measurements | |

| Dual element transducer measurement mode | Time interval from a precision delay after the excitation pulse to the first echo |

| THRU-COAT® measurement | Measurement of true metal and coating thicknesses with a single back-wall echo (with D7906-SM and D7908 transducers) |

| Thru-Paint Echo-to-Echo | Time interval between two successive back-wall echoes to eliminate paint or coating thickness |

| Single element transducer measurement modes | Mode 1: Time interval between the excitation pulse and the first back-wall echo Mode 2: Time interval between the delay line echo and the first back-wall echo (with delay or immersion transducers) Mode 3: Time interval between successive back-wall echoes following the first interface echo after the excitation pulse (with delay line or immersion transducers) Oxide: optional Multilayer mode: optional |

| `Thickness range | 0.080 mm to 635.00 mm (0.003 in. to 25.000 in.) depending on material, transducer surface conditions, temperature, and selected configuration |

| Material velocity range | 0.508 mm/μs to 13.998 mm/μs (0.020 in./μs to 0.551 in./μs) |

| Resolution (selectable) | Low: 0.1 mm (0.01 in.) Standard: 0.01 mm (0.001 in.) High Resolution (optional): 0.001 mm (0.0001 in.) |

| Transducer frequency range | Standard: 2.0 MHz to 30 MHz (-3 dB) High Penetration (optional): 0.50 MHz to 30 MHz (-3 dB) |

| General | |

| Operating temperature range | -10 °C to 50 °C (14 °F to 122 °F) |

| Keypad | Sealed, color-coded keypad with tactile and audible feedback |

| Case | Impact-resistant and water-resistant, gasketed case with sealed connectors. Designed for IP67. |

| Dimensions (W x H x D) | Overall: 125 mm x 211 mm x 46 mm (4.92 in. x 8.31 in. x 1.82 in.) |

| Weight | 0.814 kg (1.80 lb) |

| Power supply | AC/DC adaptor, 24 V; lithium-ion battery 23.760 Wh; or 4 AA auxiliary batteries |

| Battery life, lithium-ion | Operating time: minimum 12.6 h, 14 h typical, 14.7 h maximum Fast charge: 2 h to 3 h |

| Standards | Designed for EN15317 |

| Display | |

| Color transflective VGA display | Liquid crystal display, display area 56.16 mm x 74.88 mm (2.2 in. x 2.95 in.) |

| Rectification | Full wave, RF, half-wave positive, or half-wave negative |

| Inputs/Outputs | |

| USB | 1.0 client |

| RS-232 | Yes |

| Memory card | Maximum capacity: 2 GB External MicroSD memory card |

| Video output | VGA output standard |

| Internal Data logger | |

| Data logger | The 38DL PLUS identifies, stores, recalls, clears, and transmits thickness readings, waveform images, and gage configuration information through the standard RS-232 serial port or USB port. |

| Capacity | 475,000 thickness measurements or 20,000 waveforms with thickness measurements |

| File names, IDs, and comments | 32-character file names and 20-character alphanumeric location codes with four comments per location |

| File structures | Nine standard or custom application-specific file structures |

| Reports | On-gage reporting of summary with statistics, Min./Max. with locations, Min. review, file comparison, and alarm report |

Software Options

38DLP-OXIDE (U8147014): Code-activated Internal Oxide measurement software

38DLP-HR (U8147015): Code-activated High Resolution measurement software

38DLP-MM (U8147016): Code-activated Multilayer measurement software

38DLP-HP (U8147017): Code-activated High Penetration (low frequency) measurement software

38DLP-EBSCAN (U8147018): Encoded B-scan software

Optional Accessories

38DLP/EW (U8778348): Three-year warranty

1/2XA/E110 (U8767104): Filter adaptor for E110-SB EMAT transducer

38-9F6 (U8840167): RS-232 cable

38-C-USB-IP67 (U8800998): USB cable for IP67 sealed operation

38DLP/RFS (U8780288):Foot switch, factory installed

HPV/C (U8780124): Digital caliper for thickness input for velocity measurements

38DLP-V-CC (U8840172): Cable for digital caliper

EPLTC-C-VGA-6 (U8840035):VGA output cable

MICROSD-ADP-2GB (U8779307): 2 GB External MicroSD memory card

BSCAN-ENC (U8779522): Encoded B-scan buggy

38DL--ENC-CBC-10 (U8840168): 10 ft encoder cable

Thickness Measurements on Internally Corroded Metals

One of the major applications of the 38DL PLUS is measuring the remaining thickness of pipes, tubes, tanks, pressure vessels, hulls, and other structures affected by corrosion or erosion. Dual element transducers are most commonly used for these applications.

• Automatic Probe Recognition for standard D79X series dual element transducers

• Ten custom dual element transducer setups

• Optimized default gain during calibration for dual element transducer

• V-Path Builder for custom V-path compensation

• Calibration Doubling warning when echo doubling may occur during calibration

• THRU-COAT® and Echo-to-Echo measurements on painted and coated surfaces

• High temperature measurements; up to 500 °C (932 °F)

• Boiler tube and Internal Oxide measurements (optional) with M2017 or M2091 single element transducers

• EMAT transducer (E110-SB) for no-couplant measurements of boiler tubes with external oxide/scale buildup

Optional Encoded B-Scan

This powerful optional feature allows the 38DL PLUS to be connected to a

linear encoded scanner to generate encoded B-scans. The 38DL PLUS will

capture and store the distance traveled information along with corresponding

thickness readings. The waveform at the minimum thickness is also captured.

The user can select the distance between measurements and select between

bidirectional and unidirectional modes. Up to 10,000 thickness readings can

be stored in a single B-scan.

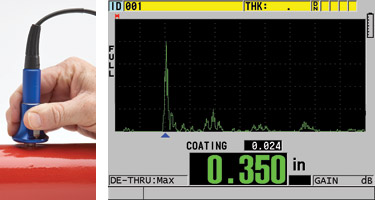

Thru-Coat® Technology

A single back-wall echo is used to measure true metal thickness. You can display the metal and coating thicknesses, each adjusted for their correct material sound velocities. There is no need to remove paint and coatings from surfaces. THRU-COAT measurements use the D7906-SM, D7906-RM, and D7908 dual element transducers.

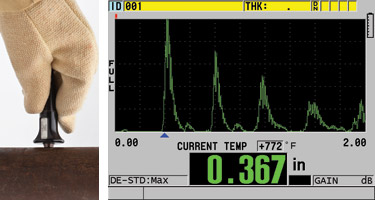

Temperature Compensation

Variations in material temperature affect sound velocity and accuracy of thickness measurements. The temperature compensation feature allows you to manually enter the calibration block's temperature and the current (high) temperature at the measurement points. The 38DL PLUS automatically displays the temperature-corrected thickness.

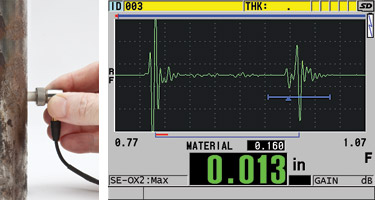

Optional Oxide/Scale Measurement

38DL PLUS uses advanced algorithms to measure the thickness of oxide/scale buildups inside boiler tubes. The gage simultaneously displays the metal thickness of the boiler tube and the thickness of the oxide layer. Knowing the thickness of the oxide/scale helps predict tube life. We recommend using M2017 or M2091 transducers in this application.

V-Path Builder

This new and patented feature allows you to build a custom V-Path compensation curve for almost any dual element transducer. These curves can be saved and recalled along with custom setups for most dual element transducers.

You simply calibrate and enter the known thickness with a minimum of 3 and up to 10 calibration points, and the instrument will create the V-path.

Automatic Probe Recognition

All standard dual element transducers feature Automatic Probe Recognition, which automatically recalls a default V-path correction for each specific transducer.

Thickness Measurements on Plastics, Metals, Composites, Glass, Rubber, Ceramics

When using single element transducers, you can make accurate thickness measurements on metals, plastics, composites, glass, ceramics, and other materials. These transducers are available in a wide range of frequencies, diameters, and connector styles. The High Resolution software option allows you to make very precise measurements at a resolution of 0.0001 in. or 0.001 mm.

• Standard resolution of 0.01 mm (0.001 in.) for all transducers

• High Resolution software option can display measurements up to 0.001 mm (0.0001 in.) for single element transducers from 2.25 MHz to 30 MHz

• High Penetration software option for measurements on attenuating materials such as fiberglass, rubber, and thick castings

• Multilayer software option for individual thickness measurements of up to four layers simultaneously

• Thickness, Velocity, or time-of-flight measurements

• Application Auto-Recall with default and custom setups to simplify thickness measurements

High Penetration Software Option

This option allows you to use low frequency single element transducers (as low as 0.5 MHz) to measure thick or sound attenuating materials such as rubber, fiberglass, castings, and composites.

Multilayer Software Option

This software option calculates and simultaneously displays thickness measurements of up to four individual layers.

It also displays total thickness of selected layers. Typical applications include thickness of barrier layers in plastic fuel tanks, bottle preforms, and soft contact lenses.

38DL PLUS Product Overview

| 38DL PLUS Thickness Gage | English - 3.1 |

| B-scan Option | English - 2.6 MB |

Ελ. Βενιζέλου 7 & Δελφών, 14452 Μεταμόρφωση, Αθήνα, Ελλάδα |