|

|

MultiScan MS5800 for Tube Inspection

Multi-technology system that offers eddy current, magnetic flux leakage, remote field, near field, and IRIS ultrasound technologies.

The MultiScan MS5800 is a multi-technology system offering these technologies:

- Eddy Current

- Magnetic Flux Leakage

- Remote Field

- IRIS Ultrasound

MS 5800E

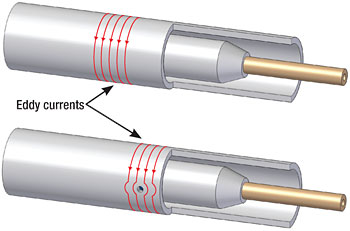

Tube Inspection with Eddy Current Testing (ECT)

- Condensers

- Feedwater heaters

- Heat exchangers

- Air conditioners

Eddy current testing is a noncontact method used to inspect nonferromagnetic tubing. This technique is suitable for detecting and sizing metal discontinuities such as corrosion, erosion, wear, pitting, baffle cuts, wall loss, and cracks in nonferrous materials.

- Two coils are excited with an electrical current, producing a magnetic field around them. The magnetic fields penetrate the tube material and generate opposing alternating currents in the material. These currents are called eddy currents.

- Any defects that change the eddy current flow also change the impedance of the coils in the probe.

- These changes in the impedance of the coils are measured and used to detect defects in the tube.

MultiScan MS 5800E Key Features

- Four simultaneous frequencies per input.

This feature allows for inspection speeds up to 2 m/s with four frequencies on absolute and differential channels, without signal distortion. - Electronic probe balancing.

No separate external reference probe is required for absolute channel operation. - 4 ECT inputs and up to 64 multiplexed channels.

The MultiScan™ MS 5800E can support a large number of ECT channels to perform array probe inspections. Compared to single-channel inspection, the array probe technology allows for faster and easier surface coverage.

MS 5800U

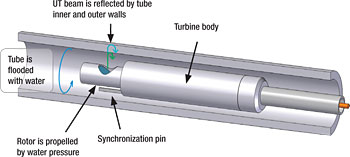

Tube Inspection with an Internal Rotating Inspection System (IRIS) for Ferrous and Nonferrous Materials

- Boilers

- Feedwater heaters

- Air coolers

- Heat exchangers

The ultrasonic IRIS option is used to inspect a wide range of materials, including ferrous, nonferrous, and nonmetallic tubing. This technique detects and sizes wall loss resulting from corrosion, erosion, wear, pitting, cracking, and baffle cuts. Olympus digital IRIS inspection technology is used extensively as a prove-up technique for remote field testing, magnetic flux leakage, and eddy current inspections.

MultiScan MS 5800U (IRIS) Key Features

- Setup wizard

Simplifies equipment calibration for different tube diameters and materials. The wizard also generates the reporting code for the inspection. - Real-time gain and gate controls

UT settings can be modified during the C-scan acquisition for quick optimization of signal detection. - Real-time and continuous color C-scans

Reduces missed flaws with C-scan displays. To enhance the quality and appearance of your reports, include color maps and cross-section views of defects. - Full tube-length recording

Used to analyze data off-line, and to assess results with customers.

MS 5800R

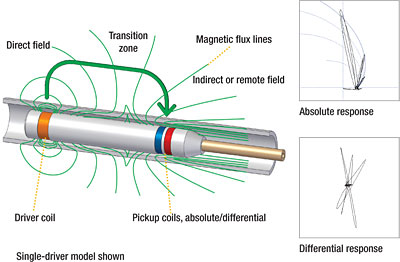

Tube Inspection with Remote Field Testing (RFT)

- Boilers

- Feedwater heaters

- Carbon steel heat exchangers

Remote field testing (RFT) is being used to successfully inspect ferromagnetic tubing such as carbon steel or ferritic stainless steel. This technology offers good sensitivity when detecting and measuring volumetric defects resulting from erosion, corrosion, wear, and baffle cuts.

Olympus remote field probes and the MultiScan™ MS 5800 are used all around the world to successfully inspect heat exchangers, feedwater heaters, and boiler tubes.

MultiScan MS 5800R Key Features (RFT)

- RFT with up to four different frequencies and real-time mixes.

This feature provides more flexibility for mixing and defect validation. The detection and sizing of flaws at the support plate is made easier with multifrequency inspections and dual-driver operations. - RFT with frequencies ranging from 20 Hz to 250 kHz.

The high frequency available with the MultiScan MS 5800R™ extends RFT inspection to thin materials with low permeability, such as 400-series stainless steel, and other ferromagnetic alloys.

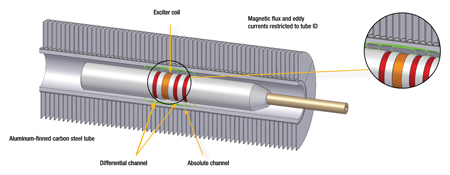

Tube Inspection with Near Field Testing (NFT)

- Air coolers

- Carbon steel heat exchangers

Near field testing (NFT) technology is a rapid and inexpensive solution intended specifically for fin-fan carbon-steel tubing inspection. This new technology relies on a simple driver-pickup eddy current probe design providing very simple signal analysis.

NFT is specifically suited to the detection of internal corrosion, erosion, or pitting on the inside of carbon steel tubing. The NFT probes measure lift-off or "fill factor," and convert it to amplitude-based signals (no phase analysis). Because the eddy current penetration is limited to the inner surface of the tube, NFT probes are not affected by the fin geometry on the outside of the tubes.

MultiScan MS 5800 R™

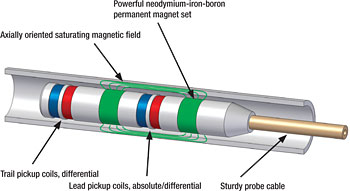

Tube Inspection with Magnetic Flux Leakage (MFL)

- Feedwater heaters

- Air coolers

- Carbon steel heat exchangers

Magnetic flux leakage (MFL) is a fast inspection technique, suitable for measuring wall loss and detecting sharp defects such as pitting, grooving, and circumferential cracks. MFL is effective for aluminum-finned carbon steel tubes, because the magnetic field is almost completely unaffected by the presence of such fins.

Eddy Current Array Multiplexer

The array technologies are highly valuable when high resolution or imagery is desired. The MultiView acquisition and analysis software features improved C-scan functionality for easy setup and analysis in a virtually unlimited number of layouts.

When used in combination with the MS5800 and the MultiView "C" option, one or two ECA multiplexer units enable array technology with ECT, RFT, NFT, or MFL technologies. While the majority of OmniScan ECA probes can be connected to the ECA multiplexer, Olympus provides the option of configuring the Tube Testing Array probes to your needs.

MS 5800 Backpack

Each MS5800 is currently delivered with the acclaimed Backpack (20ED0074, U8764077), which provides your operational staff with maximum comfort and protection. The Backpack, which was developed and tested in the field with the assistance of several service companies, also provides additional space to carry calibration tubes, probes, or adaptors.

MS 5800 Footswitch

The optional MS5800 Footswitch (TA-FSW-001, U8770248) provides productivity gains to individuals or two-person crews when recording data. With its field-proven, rugged design, it enables the operator to remotely perform the majority of common operations by programming several useful and configurable functionalities in the MultiView software, without the need to directly access the computer.

| EC/RFT/MFL/UT | |

| Setup wizard | Easy configuration for tube inspection with conventional probes |

| Automatic calibration | Simultaneous calibration of all channels and depth curves |

| Data file storage | Any PC-compatible media |

| Printing | Screen dump, acquisition, and setup reports to any Microsoft® Windows XP®-compatible printer |

| UT | |

| Measurement mode | Wall thickness: IRIS (immersion) |

| Setup display | A-scan |

| Profilometry display | Wall thickness, ID and OD color C‑scans, B-scan for tube circumferential cross section and axial section |

| Cursors | Cross-section cursors and manual pit-sizing cursors |

| Measurement | Wall loss (%), remaining wall, and statistics on tube geometry (minimum, maximum, average) |

| Software Requirements | |

| Operating system | Microsoft Windows XP Pro |

| Hardware requirements | 2 GHz Pentium® with 2 GB RAM, 1 GB of free space on a hard disk, 1024 × 768 display resolution |

| General | |

| Power | 120 VAC or 220 VAC ±10%, automatic selection, 48 Hz to 63 Hz |

| Size (excluding handle) | 45 cm x 30 cm x 22 cm |

| Weight | Maximum weight with all modules installed: 12.8 kg |

| Environment | -20°C to 45°C for ambient operation; -20°C to 70°C storage; 95% relative humidity, noncondensing |

| Computer interface | 100Base-T Fast Ethernet |

| Eddy Current Testing | |

| Probe inputs | Four independent differential inputs, and up to 64 multiplexed inputs (16 time slots) with MUX-PKG-MS (U8780060) |

| ECT channels | 16 simultaneously (4 inputs x 4 frequencies); 256 in super-multiplexed mode (with 16 time slots) |

| Number of frequencies | Up to eight frequencies |

| Frequency range | Adjustable from 20 Hz to 6 MHz |

| Acquisition rate | 40 kHz per channel (in conventional mode); 14 kHz divided by the number of time slots (in multiplexed mode) |

| Supported probes | The universal connector supports all standard differential and absolute bobbin, impedance, transmit-receive, and rotating probes. (Adaptor cable might be required.) |

| Probe balancing | True electronic probe balancing. A separate external reference probe is not required for absolute channels. |

| Output voltage | 20 Vp-p per generator (2 outputs) |

| Output current | 1 A (peak) |

| Real-time alarms | Eight independent alarms (raw channels only) |

| Encoders | Two quadrature encoders and digital inputs |

| Remote Field Testing, Near Field, and Magnetic Flux Leakage | |

| Probe inputs | Four independent inputs for RFT/NFT Four independent inputs for MFL |

| RFT/NFT channels | 16 simultaneously (4 inputs x 4 frequencies); 64 in multiplexed mode for NFT (4 inputs x 16 time slots) and eight for RFT (4 inputs x 2 time slots) |

| MFL channels | Four simultaneously 64 in multiplexed mode (4 inputs x 16 time slots) |

| Number of frequencies | Up to four frequencies (RFT only) |

| Frequency range | Adjustable from 20 Hz to 250 kHz |

| Acquisition rate | 40 kHz per channel (in conventional mode); 14 kHz divided by the number of time slots (in multiplexed mode) |

| Supported probes | Supports any differential and absolute probes with a single exciter, dual exciters, dual pickup, near field, and magnetic flux leakage. (Adaptor cable might be required.) |

| Probe balancing | True electronic probe balancing |

| Output voltage | 20 Vp-p per generator (2 outputs) |

| Output current | 1 A (peak) |

| Analog output | X and Y components of the first input |

| Real-time alarms | Eight independent alarms (raw channels only) |

| Encoders | Two quadrature encoders or digital inputs |

| Ultrasonic IRIS testing | |

| Number of pulsers/receivers | One channel in pulse-echo mode |

| System bandwidth | 0.5 MHz to 25 MHz |

| Sampling rate | 8-bit, 100 MHz |

| Transducer frequencies | 1 MHz to 20 MHz |

| Pulse repetition rate | Up to 20 kHz |

| Dynamic gain (linear amplifier) | 70 dB, 1 dB steps |

| A-scan length | 32 to 8,092 points |

| Pulse voltage | 50 V to 300 V, 1 V steps |

| High-pass filter | None, 2 MHz, 5 MHz, 10 MHz |

| Data-acquisition synchronization | Time, continuous, position, or external |

| Encoders | Two quadrature encoders and digital inputs (requires MultiView 6.1 or higher) |

| MultiScan MS5800 for Tube Inspection | English - 2.0 MB |

Ελ. Βενιζέλου 7 & Δελφών, 14452 Μεταμόρφωση, Αθήνα, Ελλάδα |