|

|

EPOCH 1000

The EPOCH 1000 is an advanced conventional ultrasonic flaw detector that can be upgraded with phased array imaging at an authorized Olympus service center. Key features include: EN12668-1 compliant, 37 digital receiver filter selections, and 6 kHz pulse repetition rate for high speed scanning.

The EPOCH 1000 Series Digital Ultrasonic Flaw Detectors combines the highest level of performance for conventional portable flaw detection with the power of phased array imaging. The EPOCH 1000, 1000 iR and 1000 i feature a new horizontal case style with full VGA display, knob and navigation arrows for parameter adjustment, and full EN12668‑1 compliance. The advanced conventional ultrasonic functionality of the EPOCH 1000 series is augmented in the EPOCH 1000 i with phased array imaging capabilities.

Key Features

- Available with Phased Array Imaging Package

- EN12668-1 compliant

- 37 digital receiver filter selections

- 6 kHz pulse repetition rate for high speed scanning

- Encoded or time-based C-scan option

- Automatic phased array probe recognition

- Intuitive wedge delay and sensitivity calibration for all focal laws

- Programmable analog/alarm outputs

- Designed for IP66 environmental rating

- Horizontal design with navigation panel and knob parameter adjustment

- Digital high dynamic range receiver

- Full VGA sunlight readable display

- ClearWave™ visual enhancement package for conventional A-scan interpretation

- SureView™ visualization feature

- Reference and measurement cursors

- Standard dynamic DAC/TVG

- Standard onboard DGS/AVG

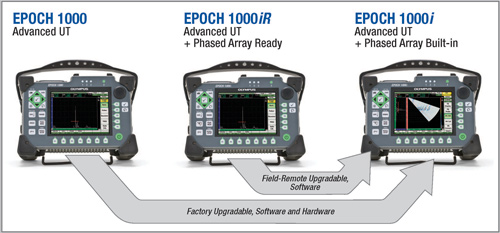

Three instrument configuration levels to suit many inspection needs.

EPOCH 1000

Advanced UT

The EPOCH® 1000 is an advanced conventional ultrasonic flaw detector that can be upgraded with phased array imaging at an authorized Olympus service center.

EPOCH 1000 iR

Advanced UT + Phased Array Ready

The EPOCH 1000 iR provides the same ultrasonic flaw detection capabilities as the EPOCH 1000 with the benefit of upgrading to phased array with simple field-remote activation.

EPOCH 1000 i

Advanced UT + Phased Array Built-in

The EPOCH 1000 i comes standard with the same advanced ultrasonic flaw detection capabilities as the EPOCH 1000, with the addition of a built-in phased array imaging package.

Key Industries and Applications

- General weld inspeciton

- Crack detection and sizing

- Power generation inspections

- AWS D1.1/D1.5 weld inspection

- Casting and forging defect inspections

- DGS/AVG defect sizing

- In-line inspections

- Composite delamination and defect inspections

- Aerospace and maintenance

- Automotive and transportation

Rugged. Portable. Meets the Demands of the Toughest Inspection Environments

The EPOCH® 1000 Series is designed to meet the IP66 environmental rating. Tested for shock, vibration, explosive atmosphere, and wide temperature range, these instruments can withstand operation in harsh inspection conditions. Some of the EPOCH 1000 Series' other key physical features include:

- Large, full VGA (640x480) resolution color transflective display for optimum viewing in low or bright lighting conditions.

- Rugged rubber handle for easy transport.

- Durable instrument-mounted D-rings for chest harness use.

- Front and rear stands for table-top or steep inclined viewing.

- USB Client and Host ports for PC communication, direct printing and communication with peripheral devices.

- VGA output for presentations, training, and remote instrument monitoring.

- Programmable analog outputs, alarm outputs, and RS-232 communication.

- Standard internal, rechargeable lithium-ion battery.

Onboard Media and Report Generation

The EPOCH 1000 series is equipped with onboard capabilities for file and database transfers, image capture, and basic reporting. These features provide you with multiple options for accessing previously stored data, in addition to live images.

Two forms of removable media, compact flash (CF) cards and USB memory sticks, can be used to export of images and reports. A compact flash (CF) card is included with every EPOCH 1000 series instrument.

Instrument Datalogger

The sophisticated data logger is designed for easy data capture for reporting of images, measurements, and calibration information. The data logger features dedicated calibration files with quick recall capability for fast setup adjustment, in addition to inspections files with either full data or basic image and measurement captures for quick reporting purposes. Advanced file types are also available for a variety of corrosion applications.

File and Database Transfers

The complete instrument database can be backed up to a USB memory stick and restored onto any EPOCH 1000 series unit. Individual files can also be copied to a USB memory stick for transfer between units.

Image Capture

Screen shots of the live instrument screen can be captured and exported using either removable media format (CF or USB). Specific file types can also be created to allow for easy export of the saved file image for use in any kind of report.

Reporting Capabilities

The enhanced reporting capabilities of the EPOCH 1000 series enable dynamic output of information in a variety of formats. Reports from stored data files can be created onboard the instrument and sent to the desired media destination (CF or USB) in HTML format. Two report options are available based on the specific information required for the report. A custom logo can be imported and used in place of the standard Olympus logo in the report header.

Specifications | |

| Format | HTML |

| Type | Summary (measurement data only) Data (complete setup and waveform) |

| Header logo | Customizable (bmp, jpg, png formats) |

PC Management and Reporting

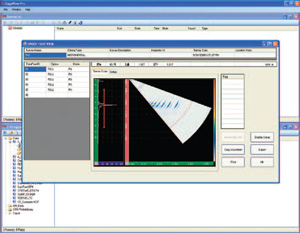

GageView™ Pro Data Software

The EPOCH 1000 series is fully compatible with GageView Pro Olympus' standard portable instrument PC interface program. The GageView Pro interface program can be used to download saved data for review, export, and backup, and to generate reports containing setup parameters, measurement data, and waveforms. Database backup files can be viewed directly in GageView Pro using a USB memory stick without having to connect the EPOCH 1000 series instrument to the PC. This feature allows for backup, data review, and report generation of instrument files without having to remove the instrument from in-field work. Other tools, including an instrument firmware upgrade utility, are also available as part of this program.

Features

- Download saved inspection data and setup files.

- Review setup information and measurements on a PC.

- Export measurements and calibration data to common spreadsheet programs.

- Back up calibration and inspection data from the instrument.

- Upgrade instrument firmware.

- Generate reports with setup parameters, measurements, and waveforms.

- Access saved data through unit database backup files.

Accessories

The EPOCH 1000 series offers various accessories to allow full functionality of available features.

- EPXT-C-VGA-6 (U8779019): VGA output cable

- EP4P/C-USB-6 (U8840084): USB client cable

- EP1000-C-RS232-6 (U8779197): RS-232 communications cable

- EP1000-C-26OUT-6 (U8779018): Hardware I/O cable (alarm outputs triggering)

- EP1000-C-9OUT-6 (U8779017): Hardware I/O cable (analog output)

- EP4/CH (U8140055): Chest harness

- EPXT-EC-X: External battery charger

- EPXT-BAT-L (U8760021): Extra battery (lithium-ion)

- EP1000-TC-S (U8764078): Small Transport Case

- EP1000-TC-L (U864079): Large Transport Case

Small Transport (P/N EP1000-TC-S)

Large Transport Case (P/N: EP1000-TC-L)

Advanced Conventional Ultrasound, Upgradable to Phased Array

The EPOCH® 1000, EPOCH 1000 iR , and EPOCH 1000 i provide advanced conventional ultrasound capabilities for both basic and advanced level users. These portable instruments can also be integrated into small systems for high speed scanning and single- channel imaging and come standard with a host of high performance features, including a 6 kHz maximum Pulse Repetition Frequency (PRF) with single-shot measurements for accurate high-speed scanning applications, tunable square wave pulser with PerfectSquare™ technology, and comprehensive digital filter sets for exceptional signal-to-noise clarity.

Pulser/Receiver Features

- Adjustable pulse repetition frequency (PRF): 5 Hz to 6 kHz.

- Single-shot measurements in all standard modes.

- Tunable Square Wave Pulser with PerfectSquare™ technology.

- Programmable analog and alarm outputs.

- Over 30 digital filter set.

- Digital high dynamic range receiver.

Standard Software Features

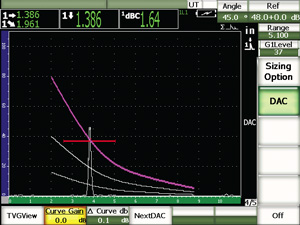

Dynamic DAC/TVG Mode

- Dynamic DAC/TVG - This standard feature enables fast and dynamic creation of DAC curves using reference reflectors, in addition to single-button switching from DAC to TVG mode. Includes ASME, ASME-III, JIS, 20% to 80% DAC, Custom, and TVG Table.

- Onboard DGS/AVG - The DGS/AVG flaw sizing technique uses calculated attenuation curves to aid you in sizing potential defects. A vast onboard library of characterized probes enables you to quickly and easily setup a DGS/AVG curve and perform precise flaw sizing.

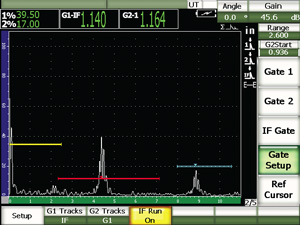

Interface Gate with 1 and Gate 2 Tracking

- Interface Gate - This optional third measurement gate enables real-time tracking of a variable interface echo in order to maintain consistent digital measurements.

- AWS Welding Rating - This weld rating calculator provides a live AWS D1.1/D1.5 code-compliant "D" value weld rating for gated flaw indications.

- Floating Gate - This option enables you to "float" Gate 1 and/or Gate 2 at a selected height compared to a gated echo (-1 dB to -14 dB). This feature provides more consistent, precise readings, especially in Edge Detection mode.

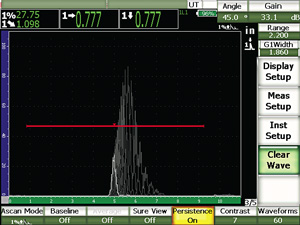

ClearWave™ Conventional Ultrasound Visual Enhancements

SureView Screen

The EPOCH® 1000 features a new and exciting set of visual enhancement capabilities to improve the quality and ease of detection in advanced applications.

- SureView® - This feature emulates the functionality of analog CRT displays, allowing you to visualize peak indications from reflectors by adding a point of light along the A-scan trace where every peak occurs.

- Composite A-scan - This feature uses every A-scan acquired in between screen update rates (multiple A-scans when PRF > 60 Hz) to draw a composite A-scan based on the maximum envelope of all the acquired A-scans. This feature increases confidence of visual detection when scanning quickly.

- Max Amplitude - This feature displays only the acquired A-scan with the highest gated amplitude reading between screen updates.

Persistence Mode Screen

- Persistence Mode - This feature retains previously acquired A-scans on the instrument display for a user-selectable duration. This feature provides visual "memory" of an inspection for enhanced visual detection over a short period

of time. - Baseline Break - This feature displays "zero-cross" points as lines connecting individual A-scan lobes to the baseline in full-wave rectified mode.

- Min Thickness - This feature displays only the A-scan representing the minimum thickness reading between screen updates.

- Averaged A-scan - This feature enables you to view the average of the acquired A-scans. Averaging is applied in multipliers of 2x, 4x, 8x, 16x, 32x, and 64x.

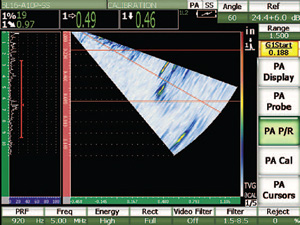

Phased Array Imaging Package with Advanced Conventional Ultrasound

The EPOCH® 1000 i provides powerful conventional ultrasonic and phased array flaw detection in a portable, rugged instrument. This instrument offers increased probability of detection of flaws, better visualization of areas of interest, and improves inspection efficiency by enabling a single setup to view A-scans at multiple angles (focal laws), thus eliminating the need for multiple probes and wedges. This instrument provides the same reliable and exceptional performance for conventional detection as the EPOCH 1000, with the added benefit of phased array capabilities. The EPOCH 1000 i allows you to perform code-compliant inspections in accordance with conventional standards, with the advantage of phased array for increased accuracy and efficiency.

Available with a standard 16:16 configuration and upgradable to 16:64 configuration via software, the EPOCH 1000 i also includes many sizing features to facilitate in flaw inspections. The instrument comes standard with A-scan and S-scan reference and sizing cursors for flaw-size evaluation.

Gain Calibration Curve

Combined A-scan and S-scan Views

The EPOCH 1000i features a standard combined A-scan and S-scan view that displays A-scan data from every angle between two user-defined start and end values. Each individual angle, collectively referred to as focal laws, can be selected to display a live A-scan enabling you to detect and characterize potential defects at multiple angles simultaneously using phased array imaging.

Calibration Across All Focal Laws

When calibrating for gain and zero offset in phased array mode, the EPOCH 1000 i utilizes single-step procedures to calibrate across all focal laws. These automated calibration procedures allow you to capture peak amplitude or TOF/distance measurements from a single reflector across all the imaging angles (focal laws). The instrument then uses the captured amplitude or TOF/distance data to adjust the gain and zero offset at each focal law so that calibrated measurements are provided for every A-scan.

Phased Array Features for Manual Imaging Inspections

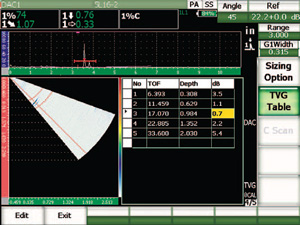

Phased Array DAC Edit Mode

Standard DAC/TVG for All Focal Laws

The EPOCH 1000 i comes standard with DAC/TVG for all focal laws. This allows you to acquire a DAC curve, or create a TVG setup from known reflectors for all defined angles/focal laws at once. The instrument then allows you to edit individual points acquired during setup for precise DAC or TVG presentation. After completing the setup, you can use the S-scan image to detect potential defects at various focal laws.

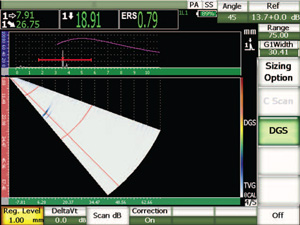

Phased Array DGS/AVG Mode

Standard Phased Array DGS/AVG

The DGS/AVG flaw sizing technique is included as a standard option in phased array mode. This feature uses the probe ID and wedge information to establish the DGS/AVG curve characteristics, and applies the curve at 0°, 45°, 60°, and 70° focal laws. The standard EPOCH onboard DGS/AVG menu and modified GAIN calibration tool allow for quick and easy setup. The option also provides an interpolated image TVG for easy detection across a given soundpath range.

Weld Inspection Solutions with Phased Array

Phased Array S-scan with Weld Overlay

Weld Overlay

Weld Overlay is a standard inclusion on the EPOCH 1000 i , providing a visual reference of a weld profile on the S-scan display. This profile enables you to visualize the relative position of indications in relation to the weld geometry.

A weld centerline cursor allows manual positioning of the overlay on the S-scan. The Weld Overlay enhances your ability to locate, characterize, and size flaws within the component during inspection, and improves reporting.

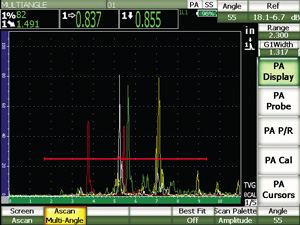

Multi-Angle Phased Array Mode

EPOCH 1000 i Multi-Angle

The EPOCH 1000 i phased array mode includes a standard feature called Multi-Angle. This feature enables you to designate any three angles, or focal laws, available in the sector scan as "visible" focal laws. The A-scans from each of the three designated angles are overlaid, one on top of the other in the A-scan window, enabling you to view all three A-scans at the same time. Each individual angle is color coded for ease of use. This feature is perfect for inspectors using conventional sizing methods requiring evaluation at 45°, 60°, and 70°.

A-scan and S-scan view with True Depth Gates

True Depth Gates

Measurements gates can be displayed in True Depth mode on the Sector Scan, thus enabling you to acquire measurements from a constant depth area throughout the part, regardless of the focal law selected. This is particularly helpful when using the encoded C-scan option, as it enables you to collect information for one entire skip distance with a single gate position.

The True Depth gates display as horizontal lines on the S-scan only; the A-scan view remains in Soundpath mode.

AWS "D" Weld Rating displayed for 45° focal law

AWS Weld Rating

The EPOCH 1000 i comes with an AWS D1.1/D1.5 weld rating calculator. In conjunction with Olympus' AWS-rated phased array transducer, this enables you to use imaging capabilities for flaw detection while sizing flaws at 45°, 60°, and 70° using the conventional A-scan technique, and also view the D value for onscreen weld rating of any selected A-scan (focal law).

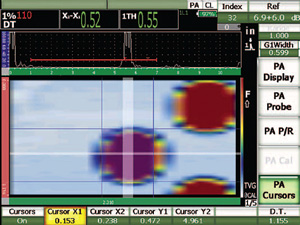

Linear Scans and Encoded C-Scans

This optional software feature expands the EPOCH 1000 i to a 16:64 element configuration and enables linear scans in addition to encoded or timed C-scans. Linear scans are collected using a probe with up to 64 elements, and a maximum active aperture of 16 elements.

C-scan imaging is created by accumulating image data from the programmed linear scan or S-scan across a single-line scan axis. An encoder is required to track the position as the probe is moved along the scan axis. This encoded C-scan image collects both time of flight (TOF) and amplitude data from two independent measurement gates. The live A-scan is viewable during C-scan acquisition. Compressed A-scan images can be stored for all points on the C-scan, and can be reviewed along with the S-scan or liner scan from a particular C-scan location for basic visual analysis. Data source and type can be adjusted dynamically after the scan is acquired, and cursors are available for basic scan sizing. Additional color palettes are available for phased array image scans. These color palettes provide different color scales for use with varied applications, and can be modified to meet your specific needs.

Zero-degree C-scan

Features

- Encoded or time based C-scans.

- Uni- or bi-directional encoding.

- Supports probes with up to 64 elements.

- Minimum scan resolution of 1 mm (0.040 in.).

- Compressed A-scan storage for all C-scan points.

- C-scan can be created from S-scan or linear scan.

- Encoding up to 3 m (118.11 in.) per scan (61 focal laws at 1 mm scan resolution).

- Image and A-Scan review for visual analysis using cursors.

Encoded C-scan Specifications | |

| Maximum File Size | 70 Mb |

| Minimum Scan Resolution | 1 mm (0.040 in.) |

| C-scan Acquisition Rate | 20 Hz |

| Saved A-scan size | 500 points |

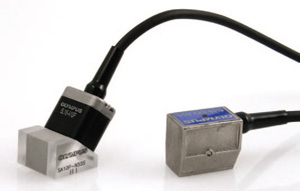

EPOCH 1000 i Phased Array Probes and Accessories

The EPOCH® 1000 i supports a new series of phased array probes to meet the demands of critical inspections. These probes include specialized probes for specific code compliance, and standard weld inspection probes, including removable or integral wedge phased array probes. Most common phased array probes with up to 64 elements are supported.

Fast Switch from Conventional to Phased Array

The EPOCH 1000 i is compatible with all standard single element transducers in conventional mode. Switching between conventional UT and phased array inspection is as easy as pressing a button. The EPOCH 1000 i features a high-speed transition from UT to PA mode, enabling you to easily combine conventional UT and phased array inspections.

Mini-Wheel Encoder

The Mini-Wheel encoder can be used with the encoded C-scan option for the positioning and dimensioning of defects in the scan axis, and can synchronize data acquisition with probe movement.

The Mini-Wheel encoder is waterproof and can be mounted onto the Olympus PA wedges using the included bracket kit. This miniature encoder is made entirely of stainless steel, and features sealed bearings for long-lasting smooth operation. The custom electronic circuit was designed for minimal noise induction.

Features

- Waterproof (designed for IP68 rating).

- Small footprint dimensions.

- Double O-ring tire for better adherence.

- Sealed bearing long lasting smooth wheel rotation.

- Strain relief for cable protection.

- Two M3 threaded holes on top of the casing for rigid attachment.

Standard Inclusions

- 1 Encoder with standard wheel

- 1 Bracket kit

- 1 Allen key screwdriver for bracket attachment

- 1 Carrying case

Phased Array Tutorial

Specifications

General

| Overall Dimensions (W x H x D) | 252 mm x 177 mm x 107 mm; 9.92 in. x 6.97 in. x 4.2 in. |

| Weight | 3.67 kg (8.1 lb), including lithium-ion battery |

| Keypad | English, International, Japanese, Chinese |

| Languages | English, Spanish, French, German, Japanese, Chinese, Russian, Italian, Polish |

| Transducer Connections | BNC or Number 1 LEMO® |

| Data Storage | Onboard up to 10,000 IDs with waveform, standard 4 GB compact flash card (removable) |

| Battery Type | Single lithium-ion rechargeable standard |

| Battery Life | 8 hours (conventional UT mode); 7 hours (phased array mode) |

| Power Requirements | AC Mains: 100 VAC to 120 VAC, 200 VAC to 240 VAC, 50 Hz to 60 Hz |

| Standby Mode | Adjustable from 15 minutes to 120 minutes with 50% less battery consumption. |

| Display Type | Full VGA (640 x 480 pixels) Transflective Color LCD, 60 Hz update rate |

| Display Dimensions (W x H, Diag.) | 132.5 mm x 99.4 mm, 165.1 mm (5.2 in. x 3.9 in., 6.5 in.) |

| Inputs/Outputs | |

| USB Ports | 1 USB Client, 3 USB Host ports |

| RS-232 | Yes |

| Video Output | VGA output standard |

| Analog Output | 4 analog outputs, Selectable 1V/10V Full Scale, 4 mA max |

| Alarm Output | 6 alarm outputs, 5V TTL, 10 mA |

| Trigger I/O | Trigger input 5V TTL; trigger output, 5 V TTL, 10 mA |

| Encoder Inputs | 2-axis encoder line (quadrature) |

| Environmental Ratings | |

| IP Rating | Designed to meet requirements of IP66 |

| Explosive Atmosphere | Tested to MIL-STD-810F, Method 511.4, Procedure 1. Atmosphere defined per NFPA 70, Article 500 as Class I, Division 2, Group D. |

| Shock Tested | IEC 600689-2-27, 60 g's, 6 µsec Half-Sine, 18 Axes total |

| Vibration Tested | Sine vibration, IEC 60068-2-6, 5 Hz to 150 Hz @ 0.03 in. or 2 g's Displacement Amplitude, 20 sweep cycles |

| Operating Temperature | -10° C to 50° C (-14° F to 122° F) |

| Battery Storage Temperature | -20° C to 60° C (-4° F to 140° F) |

| Battery Recharge Temperature | 0° C to 40° C (32° F to 104° F) |

| Epoch 1000i Phased Array Specifications | |

| Focal Laws | 61 |

| Physical Probe | 64 elements |

| Virtual Probe | 16 elements |

| Video Filtering | Off, Low, High |

| Display Modes | A-scan, S-scan, Linear scan, C-scan, A-scan plus image |

| Image Update Rate | 60 Hz update for all A-scans; 20 Hz update for all images |

| EPOCH® 1000, EPOCH 1000iR, EPOCH 1000i (conventional UT mode) | EPOCH 1000i (PA mode) | |

| Pulser | ||

| Pulser Type | Tunable Square Wave | |

| PRF | 5 Hz to 6000 Hz in 5 Hz increments | Manually adjustable. Maximum 1520 Hz |

| Energy Settings | 50 V to 475 V in 25 V increments | 40 V or 80 V |

| Pulse Width | Adjustable from 45 ns to 5,000 ns (0.1 MHz) with PerfectSquare™ Technology | Adjustable from 45 ns to 1,000 ns (0.5 MHz) with PerfectSquare™ Technology |

| Damping | 50, 100, 200, 400 Ω | Not applicable |

| Pulser Delay | Not applicable | 0 to 10 µs, 2.5 ns resolution |

| EPOCH 1000, EPOCH 1000iR, EPOCH 1000i (conventional UT mode) | EPOCH 1000i (PA mode) | |

| Receiver | ||

| Gain | 0 to 110 dB | 0 to 80 dB |

| Maximum Input Signal | 20 Vp-p | 250 mVp-p per channel |

| Receiver Input Impedance | 400 Ω ± 5% | 50 Ω ± 10% |

| Receiver Bandwidth | 0.2 to 26.5 MHz @ -3 dB | 0.5 to 12.5 MHz @ -3 dB |

| Receiver Delay | NA | 0 to 10 µs, 2.5 ns resolution |

| Digital Filter Settings | Standard filter set (EN12668-1 Test & Compliant): 7 filters Advanced filter set (not tested to EN12668-1): 30 filters | 6 filters |

| Rectification | Full wave, positive half wave, negative half wave, RF | |

| Reject | 0 to 80% FSH with visual warning | |

| Amplitude Measurement | 0% to 110% full screen height with 0.25% resolution | |

| Measurement Rate | Equivalent to PRF in all models | |

| EPOCH 1000, EPOCH 1000iR, EPOCH 1000i (conventional UT mode) | EPOCH 1000i (PA mode) | |

| Calibration | ||

| Automated Calibration | • Velocity, Zero Offset • Straight Beam (first back wall or echo-to-echo) • Angle Beam (Soundpath or Depth) | • Velocity, Zero Offset, Sensitivity • Soundpath or Depth (Zero Offset) |

| Test Modes | Pulse Echo, Dual, or Through Transmission | Pulse Echo |

| Units | Millimeters, inches, or microseconds | |

| Range | 3.33 mm to 26,806 mm (0.131 in. to 1054.1 in.) at 5900 m/s (0.2320 in./µs) | 61 focal laws, 3.33 mm to 390.95 mm (0.131 in. to 15.373 in.) at 5900 m/s (0.2320 in./µs) |

| Velocity | 635 m/s to 15,240 m/s (0.0250 in./µs to 0.6000 in./µs) | |

| Zero Offset | 0 µs to 750 µs | Automatic for all focal laws through calibration, or Manually adjustable from 0 to 100.00 µs (Global Delay Offset mode) |

| Display Delay | -59 mm to 25,400 mm (-2.323 in. to 1000 in.) | 0 to max range |

| Refracted Angle | 0° to 85° in 0.1° increments | 61 angular focal laws, 0.5°, 1.0°, 1.5°, or 2.0° increments Adjustable from -80° to +80° |

| EPOCH 1000, EPOCH 1000iR, EPOCH 1000i (conventional UT mode) | EPOCH 1000i (PA mode) | |

| Gates | ||

| Measurement Gates | Two fully independent gates for amplitude and time-of-flight measurements | |

| Measurement Mode | Soundpath | Soundpath, Depth |

| Interface Gate | Optional, with Gate 1 and Gate 2 tracking | Not applicable |

| Gate Start | Variable over entire displayed range | |

| Gate Width | Variable from gate start to end of displayed range | |

| Gate Height | Variable from 2% to 95% full screen height | |

| Alarms | • Positive and negative threshold • Minimum depth | • Positive and negative threshold (for selected focal law) • Minimum depth (for selected focal law) |

| Reference Cursors | 2 reference cursors for A-scans | 2 reference cursors for A-scans; 4 reference cursors for images |

_

| EPOCH 1000, EPOCH 1000iR, EPOCH 1000i (conventional UT mode) | EPOCH 1000i (PA mode) | |

| Measurements | ||

| Displayed Measurement | 6 locations available (manual or auto selection) | |

| Gate 1 | Thickness, soundpath, projection, depth, amplitude, time-of-flight, min/max. depth, min/max. amplitude | |

| Gate 2 | Same as Gate 1 | |

| IF Gate (optional) | Thickness | Not Applicable |

| Echo-to-Echo | Standard. Choose between Gate2-1, Gate2-IF, Gate1-IF | |

| Other Measurements | Overshoot (dB) value for DGS/AVG, ERS(equivalent reflector size) for DGS/AVG, AWS D1.1/D1.5 rating (D), reject value | |

| DAC/TVG | Standard | |

| DAC Points | Up to 50 points, 110 dB dynamic range | Up to 20 points, 40 dB dynamic |

| Special DAC Modes | 20% to 80% DAC, Custom DAC (up to 6 curves) | Not Applicable |

| TVG Table | Up to 50 points, 110 dB dynamic range, compatible with IF Gate at all PRF settings | Up to 20 points, 40 dB dynamic |

| Curved Surface Correction | Standard. Tube or bar OD correction for angle beam measurements | |

The EPOCH 1000 Series, as part of its high-level conventional UT performance, offers an encoded B-scan option that includes both single value and cross-sectional B-scan modes. This B-scan option features fast scanning speeds combined with fine scan resolution allowing for detailed scans while reducing overall scan time. EPOCH 1000 Series B-scan also allows storage of A-scans for all collected B-scan points for reporting or data validation at specific locations along the scan. Once a scan is stored, basic on-board analysis can be performed using sizing cursors on the scan image and calculated statistics from the thickness data.

Single Value B-scan

Single value B-scans, typically used in corrosion inspections, display a side profile of a test material using collected thickness readings and transducer position. These images illustrate and help users depict the internal structure of test materials. The single value B-scan on the EPOCH 1000 Series includes:

- Scanning resolution down to to 0.005 in. (0.13 mm)

- Rapid scanning speed of up to 6 in./sec (152.4 mm/sec) at minimum resolution

- Over 1 million thickness readings per B-scan without A-scan storage

- A-scan storage available for all B-scan points

- Sizing cursors and statistics available for basic on-board analysis

- Included Floating Gate software improves precision and consistency of thickness readings

- Ability to scroll and review internally stored B-scan data

- Operates in all test modes including Time Varied Gain

Cross Sectional B-scan

Cross sectional B-scans display an amplitude based image of thickness data over a scanned distance, rather than a single thickness reading at each transducer location. These scans, similar to phased array zero degree linear scans, allow visualization of flaws across the entire screen range, and are ideal for laminar flaw inspections in materials such as composites as well as base metal inspections.

- Amplitude data is displayed for entire screen range regardless of gate position

- A-scan images are stored at each transducer location and can be reviewed for further evaluation or verification

- Standard case immersion probes are often used in place of a dual element probe

- Multiple scan palettes available for various color scales

Ordering Information

An encoder buggy, transducer cable are required in addition to the B-scan software and encoder cable listed below.

| Part Number | Item Number | Description |

| EP1000-BSCAN | U8140154 | BSCAN Software Option for the EPOCH 1000 |

| EP1000-ENC-CBL-10 | U8140156 | EP1000 B-scan Encoder Cable, 10 feet |

| EP1000-ENC-CBL-25 | U8140157 | EP1000 B-scan Encoder Cable, 25 feet |

| EP1000-ENC-CBL-50 | U8140158 | EP1000 B-scan Encoder Cable, 50 feet |

| EP1000-ENC-CBL-100 | U8140159 | EP1000 B-scan Encoder Cable, 100 feet |

| EP1000-BSCAN-KIT-10 | U8140160 | BSCAN Kit for EP1000 (B-scan software, encoder buggy, 10 ft encoder cable) |

| EP1000-BSCAN-KIT-25 | U8140161 | BSCAN Kit for EP1000 (B-scan software, encoder buggy, 25 ft encoder cable) |

| EP1000-BSCAN-KIT-50 | U8140162 | BSCAN Kit for EP1000 (B-scan software, encoder buggy, 50 ft encoder cable) |

| EP1000-BSCAN-KIT-100 | U8140163 | BSCAN Kit for EP1000 (B-scan software, encoder buggy, 100 ft encoder cable) |

| EPOCH 1000 Ultrasonic Flaw Detectors | English - 1.5 MB |

Ελ. Βενιζέλου 7 & Δελφών, 14452 Μεταμόρφωση, Αθήνα, Ελλάδα |